Model Series: LSRFBM80/VHB, LSRFBM80/VHB2, LSRFBM160/VHB

Refrigerant: R32, 33 % lower GWP than R410A for reduced carbon impact

Cooling Capacity (35 °C): 40 kW (single), 80 kW (dual)

EER (35 °C): 2.8 W/W

Heating Capacity: Up to 122 kW at –5 °C ambient, up to 200 kW at 20 °C

COP Range: 2.24 to 4.61 depending on test condition

Ambient Range: Cooling –20 °C to +48 °C; Heating –35 °C to +43 °C

Airflow Design: Side-outlet horizontal (80 kW) or top-outlet vertical (all models)

Modularity: Up to 16 units paralleled for 2,560 kW maximum capacity

Installation: Water-pipe–only connections; factory-sealed refrigerant circuits

HONWO R32 EVI Inverter Commercial Air Cooled Modular Chiller is a high-performance, scalable solution delivering up to 80 kW cooling and 200 kW heating per module with R32 refrigerant, EVI (Enhanced Vapor Injection), and full DC inverter scroll compressors for COPs up to 4.61 at A20/W20 and 2.8 EER at A35/W7. Designed for commercial buildings—offices, hotels, shopping malls, and hospitals—its modular architecture allows up to 16 units to be combined for multi-megawatt capacity, while horizontal or vertical airflow configurations adapt to diverse mechanical-room layouts. Operating from –20 °C to +48 °C ambient, with built-in electronic expansion valves, dual-pressure sensors, and comprehensive protections, this chiller provides reliable heating, cooling, and domestic hot water with minimal footprint.

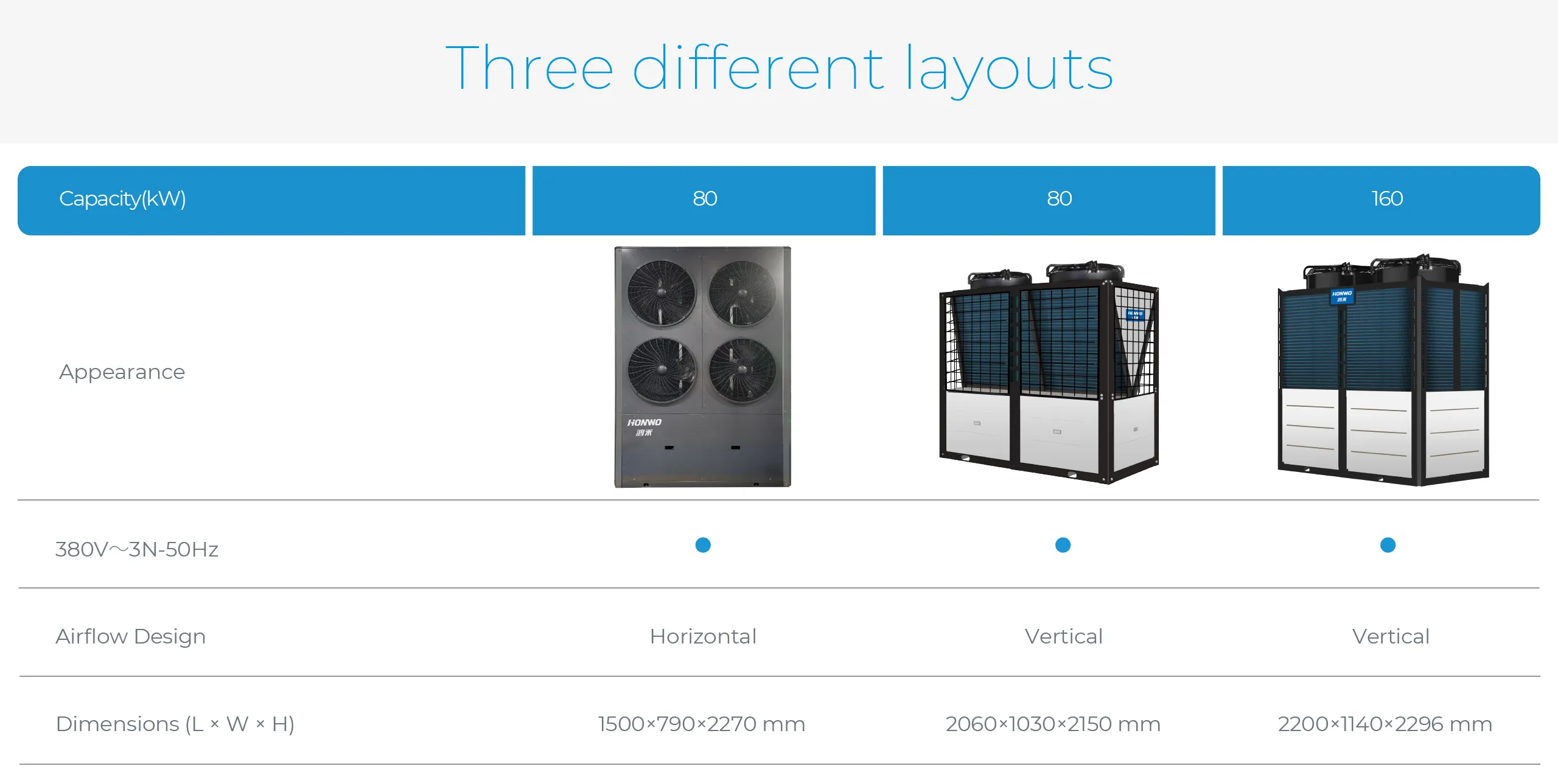

The R32 inverter modular chiller has three different layouts, which can provide cooling/heating capacity. However, the LSRFBM80/VHB adopts a side air outlet design, providing a very compact floor space. This makes this series a very good solution for projects dealing with space problems.

Enhanced Vapor Injection maintains high heating capacity and COP in sub-zero conditions, while DC inverter scroll compressors adjust speed to match load, yielding seasonal efficiencies up to A+++ equivalent.

Combine up to 16 modules under a single control system to tailor capacity to building load profiles, simplifying expansion and phased installations.

Reliable cooling from –20 °C to +48 °C and heating down to –35 °C ambient, extending comfort and hot-water availability in extreme climates.

Integrated electronics manage three electronic expansion valves and dual-pressure sensors for optimized refrigerant flow; built-in protections against high/low pressure, freezing, over-current, and fan overload ensure uptime.

Office Complexes & High-rises: Centralized cooling, heating, and DHW via scalable modules.

Hotels & Resorts: Modular capacity for guest-room wings and conference centers.

Hospitals & Schools: Redundant module operation for critical services and smooth maintenance.

Shopping Malls & Retail: Zoning flexibility and minimal footprint in plant rooms.

Certifications: CE, RoHS, ISO 9001 quality assurance.

Testing & Compliance: Performance validated to EN14511 standards (EER/COP) and EN14825 seasonal efficiency metrics.

Warranty: 2 years parts & labor, extended options available.

Service Network: Authorized partners and rapid spare-parts distribution across key markets.

| Model | LSRFBM80/VHB | LSRFBM80/VHB2 | LSRFBM160/VHB | ||

| Airflow design | Horizontal (Side-outlet) | Vertical (Top-outlet) | Vertical (Top-outlet) | ||

| Rated cooling (35℃) |

Cooling capacity | kW | 40 | 40 | 80 |

| Power input | kW | 14 | 14 | 29 | |

| EER | W/W | 2.8 | 2.8 | 2.8 | |

| Rated heating1 (20℃) |

Heating capacity | kW | 100 | 100 | 200 |

| Power input | kW | 22 | 22 | 44 | |

| COP | W/W | 4.61 | 4.61 | 4.55 | |

| Rated heating2 (7℃) |

Heating capacity | kW | 80 | 80 | 160 |

| Power input | kW | 22 | 22 | 44 | |

| COP | W/W | 3.6 | 3.6 | 3.61 | |

| Nominal heating (-12℃) |

Heating capacity | kW | 58 | 58 | 112 |

| Power input | kW | 23 | 23 | 45 | |

| COP | W/W | 2.5 | 2.5 | 2.51 | |

| Low temperature heating (A-5℃,W55℃) |

Heating capacity | kW | 63 | 63 | 122 |

| Power input | kW | 21 | 21 | 40 | |

| COP | W/W | 3.03 | 3.03 | 3.04 | |

| Nominal heating (-20℃) |

Heating capacity | kW | 47 | 47 | 90 |

| Power input | kW | 21 | 21 | 40 | |

| COP | W/W | 2.24 | 2.24 | 2.25 | |

| Outdoor unit power supply | / | 380V~3N-50Hz | 380V~3N-50Hz | 380V~3N-50Hz | |

| Maximum water outlet temperature | ℃ | 60 | 60 | 60 | |

| Maximum input power | kW | 35 | 35 | 70 | |

| Maximum input current | A | 65 | 65 | 130 | |

| Compressor | Type | EVI Inverter Scroll | EVI Inverter Scroll | EVI Inverter Scroll | |

| Quantity | 1 | 1 | 2 | ||

| Model | SAVE135D45ULG | SAVE135D45ULG | SAVE135D45ULG | ||

| Brand | GMCC | GMCC | GMCC | ||

| Fan Motor | Type | DC inverter axial fan | DC inverter axial fan | DC inverter axial fan | |

| Quantity | 4 | 2 | 2 | ||

| Power | W | 200 | 1130 | 1710 | |

| Model | Motor: RD200HC1 + Fan: 608×198 | 710 | 900 | ||

| Brand | LT Motor + Sunwill Fan | LEKVA | LEKVA | ||

| Air side condenser | Pipe diameter | mm | 7 | 7 | 7 |

| Number of holes | 68*3 | 92*2 | 104*2 | ||

| Quantity | 1 | 2 | 4 | ||

| Number of rows | 3 | 2 | 3 | ||

| Water side condenser | Type | Coaxial copper tube heat exchanger | Coaxial copper tube heat exchanger |

Coaxial copper tube heat exchanger |

|

| Water flow rate | m³/h | 14 | 14 | 27.5 | |

| Water pressure drop | Kpa | 55 | 55 | 60 | |

| Pipe diameter | / | DN50 | DN50 | DN80 | |

| Brand | Shenshi | Shenshi | Shenshi | ||

| Electronic expansion valve | Quantity | 3 | 3 | 6 | |

| Main road | Dunan/DPF(B)4.5C-P007*2 | Dunan/DPF(B)4.5C-P007*2 | Dunan/DPF(B)4.5C-P007*2 | ||

| Secondary road | Dunan/DPF(B)2.4C-101 | Dunan/DPF(B)2.4C-101 | Dunan/DPF(B)2.4C-101 | ||

| Pressure sensor | Quantity | 2 | 2 | 4 | |

| Brand/Model | / | Dunan/HVB50.0S23/HVB20.0S23 | Dunan/HVB50.0S23/HVB20.0S23 | Dunan/HVB50.0S23/HVB20.0S23 | |

| 4 – way valve | Quantity | 1 | 1 | 2 | |

| Brand/Model | / | Sanhua/SHF-50-79G44 | Sanhua/SHF-50-79G44 | Sanhua/SHF-50-79G44 | |

| Liquid reservoir | Model/Volume | CG7.5-165-16/8.5L | CG7.5-165-16/8.5L | CG7.5-165-16/8.5L | |

| Oil separator | Model/Volume | YFLQ-06VA/3.7L | YFLQ-06VA/3.7L | YFLQ-06VA/3.7L | |

| Gas-liquid separator | Model/Volume | FG15-219-35HH/17L | FG15-219-35HH/17L | FG15-219-35HH/17L | |

| Maximum working pressure(Mpa) | Heat exchanger side | Mpa | 4.5 | 4.5 | 4.5 |

| Inhalation side | Mpa | 1.5 | 1.5 | 1.5 | |

| Exhaust side | Mpa | 4.5 | 4.5 | 4.5 | |

| Control mode | / | Full inverter + three electronic expansion valves + dual pressure sensor control | Full inverter + three electronic expansion valves + dual pressure sensor control | Full inverter + three electronic expansion valves + dual pressure sensor control/single system | |

| Protective device | / | Protection against exhaust, high pressure, low pressure, current, freezing, icing, and fan overload. | Protection against exhaust, high pressure, low pressure, current, freezing, icing, and fan overload. | Protection against exhaust, high pressure, low pressure, current, freezing, icing, and fan overload. | |

| Dimensions (L × W × H) | Housing | mm | 1500×790×2270 | 2060×1030×2150 | 2200×1140×2296 |

| Net weight | kg | 510 | 530 | 1360 | |

| Refrigerant | Type | / | R410A | R410A | R410A |

| Filling Volume | kg | 13 | 13 | 13*2 | |

| Noise | dB(A) | 65 | 66 | 68 | |

| Unit functions | Heating/Cooling/DHW | Heating/Cooling/DHW | Heating/Cooling/DHW | ||

Why

We have standards from the United States, Europe, and Australia.

We have our own factory and offer the most direct factory prices.

We have a highly educated R&D team dedicated to the research and development of various HVAC products

We have four CNAS laboratories certified by ETL, and our products undergo strict quality control.

The product complies with certifications such as CE, LVD, EMS, ErP, ETL, Keymark, SG Ready, etc.

Our production process is highly automated, reducing manual errors.

Related

news

Contact